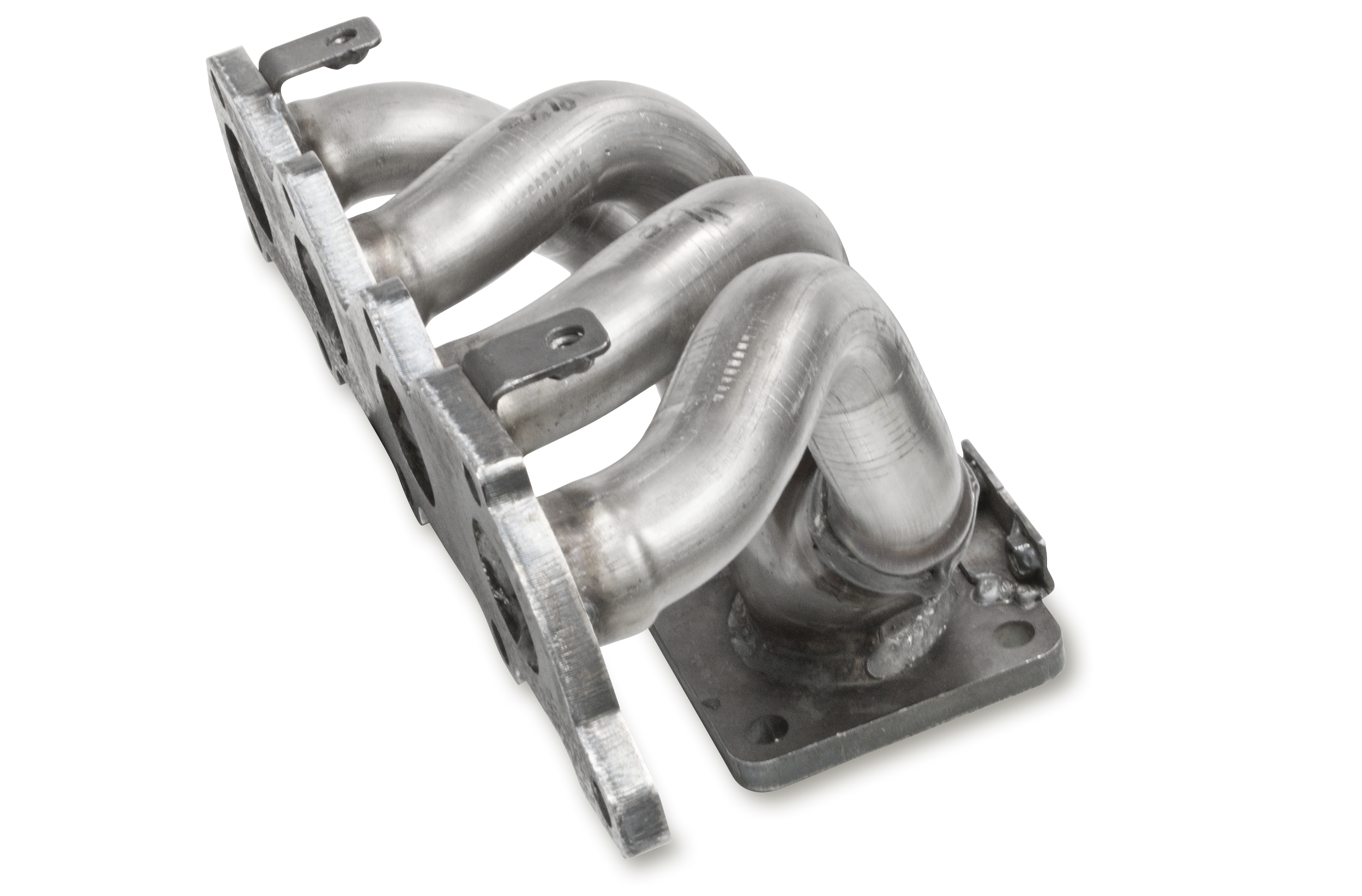

Exhaust manifold

As a sensitive, flow-relevant, component part of the exhaust gas system on the internal combustion engine, the exhaust manifold is responsible for collecting the exhaust gases expelled from the individual cylinders and routing it as required.

In this case, a demanding task is placed on the complex and flow-technically optimised component part. Both the dimensioning and highest fit accuracy on the cylinder head, the severe thermal demand through the peak temperatures at the turbo-charger, as well as the requirements on sealing with respect to other exhaust gas components, place the highest demands on the manifold.

HJS refers to development knowledge acquired over years in the thermodynamic structuring of exhaust gas component parts, as well as knowledge of the raw materials involved in steel and casting manufacture.

A hair crack in the exhaust manifold can incorrectly affect the ex-works engine control.

Thus this manifold entrains “secondary air”, through which the Lambda sensor transmits incorrect measured values to the engine electronics. With the sensitive exhaust gas values and applicable environmental laws, secondary air is a fault situation which must be excluded.

In order to simplify this process, all required built-in parts, such as seals, bolts and nuts, are included in the delivery of HJS manifolds.

Advantages:

- Highest level of fit accuracy

- Thermodynamic layout

- High-quality raw material usage

- including all required built-in parts in the scope of delivery

Go to HJS UK

Go to HJS UK