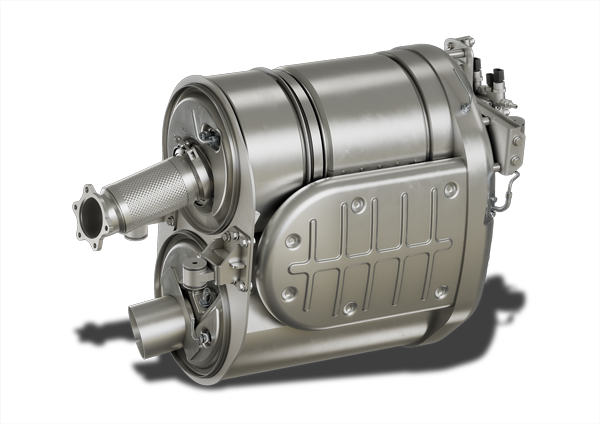

SCRT

As early as the 1990s, soot particles could be eliminated from diesel exhaust gases down to the detection limit. HJS has specially developed the diesel particle filter from sintered metal (Sintered Metal Filter SMF®) for this and received the German Environmental Prize for it.

For the reduction of the gaseous pollutants, in combination with the diesel particle filter, jointly with the project partners Daimler and JohnsonMatthey, HJS has developed the SCRT® system (Selective Catalytic Reduction + Trap). With this modular structured system, nitrogen oxides are also removed almost completely from the diesel exhaust gases.

Functioning method

For the reduction of the soot gathered in the SMF®, the well-proven HJS-SMF® technology with passive regeneration is used. Thus the upstream-connected oxidation catalyst converts the nitric oxide (NO) present in the exhaust gas into nitrogen dioxide (NO2). Then the particle filter uses the generated nitrogen dioxide (NO2) for the continuous combustion of the soot residues (soot oxidation).

Meanwhile, for the decrease of the nitrogen oxides (NOx), the downstream SCR system (SCR = Selective Catalytic Reduction) comes into play. For the application of the nitrogen oxides, an additional operating material on urea base (brand name AdBlue®), which is added to the exhaust gas mostly in the direction of flow after the diesel particle filter, is to be entrained. In the hot exhaust gas, the AdBlue® is converted thermally and catalytically to ammonia (NH3). This ammonia now acts as reducing agent for the nitrogen oxides (NOx) and converts these into innocuous nitrogen (N2) and water (H2O) at the SCR catalyzer. The SCR unit thus reduces environmental pollution, as well as health-endangering nitrogen oxide emissions, of diesel engines by up to 99 percent. Together with the HJS particle filter, the SCR system thus reduces almost all pollutants in diesel exhaust gases (SCRT® System = DPF + SCR system).

Area of application

TheSCRT®system is used both in the private car and commercial vehicle sectors, and is the leading system architecture with vehicles of generation Euro VI/ 6 or EPA 2010 when it involves clean exhaust gases. In addition, at the latest from 2019, Stage V will also be standard on a lot of `Non-Road ‘ diesel engines, i.e. for example in employment on construction machines as well as agricultural and forestry machines. This technology is also used for fixed in place engines or railways and shipping. HJS SCRT® systems are available both for application in the original equipment and for retrofit.

Go to HJS UK

Go to HJS UK